Into yokuqala ekufuneka inikwe ingqwalasela ekhethekileyo kukuba xa ujonga i-terminals yokudibanisa ngaphakathi okanye ngaphandle komatshini we-welding, amandla kufuneka acinywe.

1. Jonga rhoqo;umzekelo, khangela ukuba i-fan yokupholisa ijikeleza ngokufanelekileyo xa umatshini welding evuliwe;nokuba kukho ukungcangcazela okubi, izandi namavumba;okanye igesi;ingaba izinto ezidibeneyo kunye nokugubungela iingcingo ze-welding zikhululekile okanye zihlutha;ukuba iingcingo zokuwelda zikhululekile okanye ziyaxobuka nokuba kukho ubushushu obungaqhelekanga kulo naliphi na ilungu.

2. Ngenxa yokupholisa umoya okunyanzeliswayo kumatshini we-welding, kulula ukukhupha uthuli oluvela kwindawo ejikelezileyo kwaye uqokelele ngaphakathi kumatshini.Ngoko ke, sinokusebenzisa umoya ococekileyo kunye nowomileyo rhoqo ukususa uthuli kumatshini we-welding.Ngokukodwa, iindawo ezinje ngee-transformers, i-reactors, izithuba phakathi kweekhoyili, kunye nezixhobo zokulawula i-elektroniki kufuneka zicoceke ngakumbi.

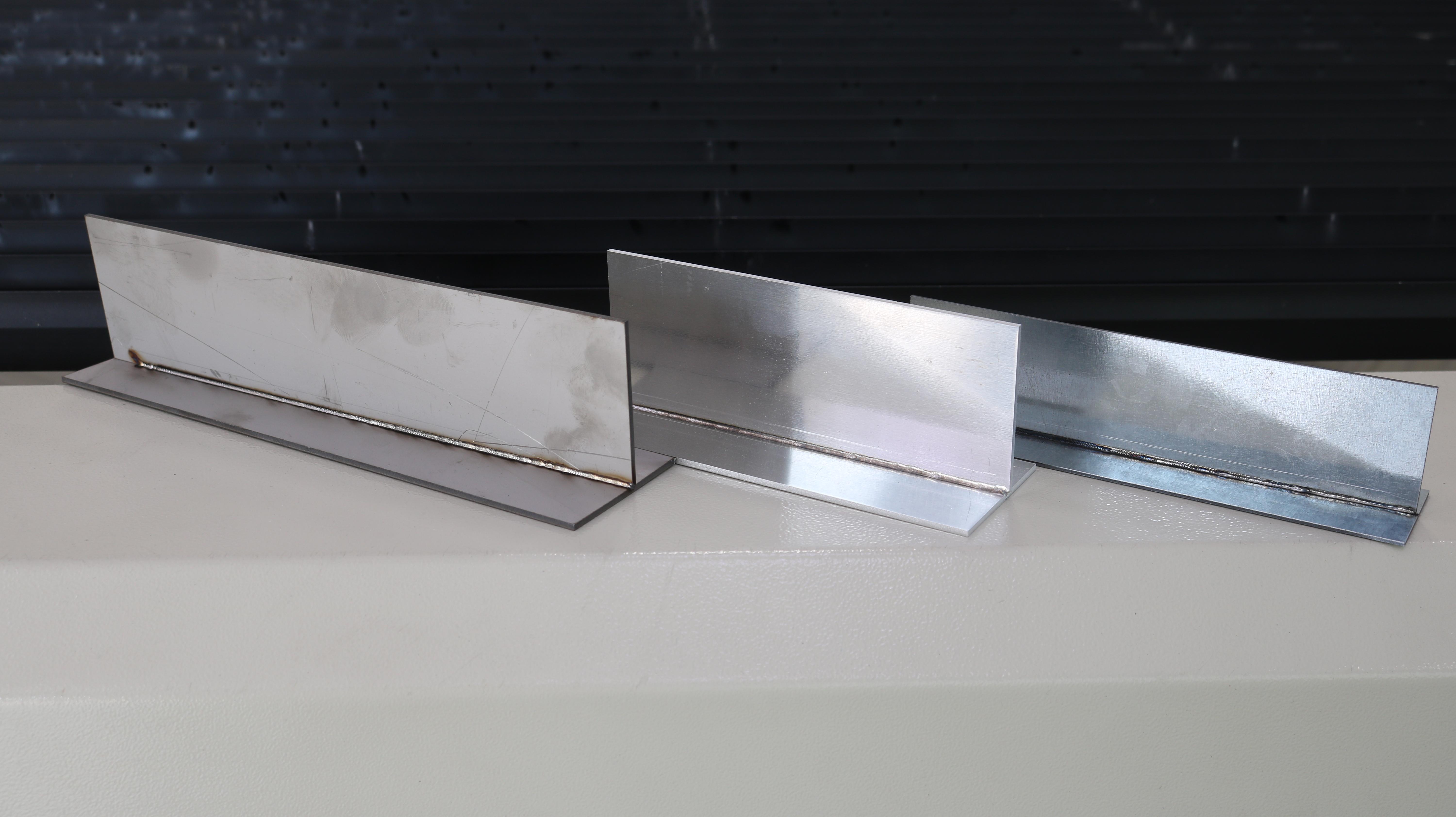

3. Ngalo lonke ixesha khangela indawo yeentambo zombane.Khangela ukuba i-terminal screws kwicala lokufaka, i-output side, njl., iindawo ze-wiring zangaphandle, iinxalenye ze-wiring yangaphakathi, njl.Ukuba kukho i-rust, yisuse kwaye uqinisekise ukudibanisa okulungileyo.

4. Ukusetyenziswa kwexesha elide lomatshini we-welding ngokuqinisekileyo kuya kubangela ukuba i-casing yangaphandle ibe yintlupheko, igrunjwe kwaye yonakaliswe ngenxa yoqhagamshelwano, kwaye iindawo zangaphakathi ziya kuphinda ziguge.Ngoko ke, ngexesha lokugcinwa nokuhlolwa konyaka, kufuneka kulungiswe ngokupheleleyo, njengokutshintsha iindawo eziphosakeleyo, ukulungiswa kwezindlu, kunye nokomeleza iinxalenye ezine-insulation eyonakele.Amalungu anesiphene angatshintshwa ngeemveliso ezintsha ngokukhawuleza ngexesha lokugcinwa ukuqinisekisa ukusebenza komatshini we-welding.

Ukugcinwa kunye nokuhlolwa rhoqo ngasentla kunokunciphisa inani lokungaphumeleli kwe-welding, efuna ixesha kunye nomsebenzi, kodwa unokwandisa ubomi bomatshini we-welding, ukuphucula ukusebenza kakuhle, ukuqinisekisa ukusebenza komatshini we-laser welding kunye nokuphucula ukhuseleko.engenakuhoywa xa i-welding.umxholo obalulekileyo.