Ukucocwa kweLaser kunye nokucholwa ziindlela ezimbini ezahlukeneyo zokunyanga umphezulu wesinyithi. Ukucocwa kweLaser yinkqubo yokunyanga umphezulu wesinyithi esebenzisa umqadi welaser okhutshwa yilaser generator ukuvelisa amandla aphezulu ukususa umhlwa, ipeyinti yokuhluba, kunye nokususa iingubo zokwaleka. I-Pickling yindlela yonyango esetyenziselwa ukususa umhlwa, amabala, ukungcola, okanye ungcoliseko kumphezulu wesinyithi.

Ukukha

Iphepha le-pickling lenziwe kumgangatho ophezulu wephepha elishushu elishushu njengento ekrwada, kwaye i-oxide layer isuswa yiyunithi yokukhetha, inqunywe, kwaye igqityiwe. Imveliso ephakathi phakathi kwamacwecwe, kwisiseko sokuqinisekisa umgangatho ophezulu kunye neemfuno zokusetyenziswa, yenza abasebenzisi ukuba banciphise ngokufanelekileyo iindleko zokuthenga.

Pickling Sheets Izinto eziluncedo

1. Umgangatho womphezulu ulungile, kuba isikali se-iron oxide sisuswe kwi-pickling plate eshushu, ephucula umgangatho ophezulu wentsimbi kwaye iququzelele i-welding, i-oiling kunye nepeyinti.

2. Ukuchaneka okuphezulu kwe-dimensional, emva kokunciphisa, i-plate shape inokutshintshwa kwinqanaba elithile, ngaloo ndlela inciphisa ukuphambuka kokungalingani.

3. Ukuphucula ukugqitywa komphezulu kunye nokuphucula ukubonakala.

Usetyenziso

Kunokuthiwa ukuba i-pickling sheet iyimveliso enexabiso eliphantsi phakathi kwephepha elipholileyo kunye nephepha elishushu. Inoluhlu olubanzi lwezicelo kushishino lweemoto, ishishini loomatshini, izixhobo zombane ezikhanyayo kunye neendawo zokutywina zemilo eyahlukeneyo, njengeemitha, iiplanga, iirim, ii-spokes, iipaneli zeenqwelo, iifeni, iidrum zeoyile yekhemikhali, imibhobho edityanisiweyo, iikhabhathi, iingcingo, iileli zentsimbi, njl.njl., zinethemba elibanzi lemarike. Ngezantsi siza kwazisa inkqubo yobugcisa benkqubo yokukhetha.

UmGaqo wokuPickling

I-Pickling yinkqubo engaphezulu esebenzisa isisombululo se-asidi ukususa isikali kunye nomhlwa phezu kwentsimbi, ngokuqhelekileyo kunye ne-pre-filming. Ngokuqhelekileyo, i-workpiece intywiliselwa kwisisombululo sekhemikhali esifana ne-asidi ye-sulfuric ukususa i-oxides kunye nezinye iifilimu kwi-metal surface, okuyiyo yonyango lwangaphambili okanye unyango oluphakathi lwe-electroplating, i-enamel, i-rolling kunye nezinye iinkqubo. Ikwaziwa njengokucoca okumanzi.

Inkqubo pickling ikakhulu ibandakanya diphu indlela pickling, ukutshiza indlela pickling kunye neasidi intlama ukurusa indlela yokususa.

Iiasidi ezisetyenziswayo ubukhulu becala yi-asidi yesulfuric, i-hydrochloric acid, i-phosphoric acid, i-nitric acid, i-chromic acid, i-hydrofluoric acid kunye ne-acids exutywe.

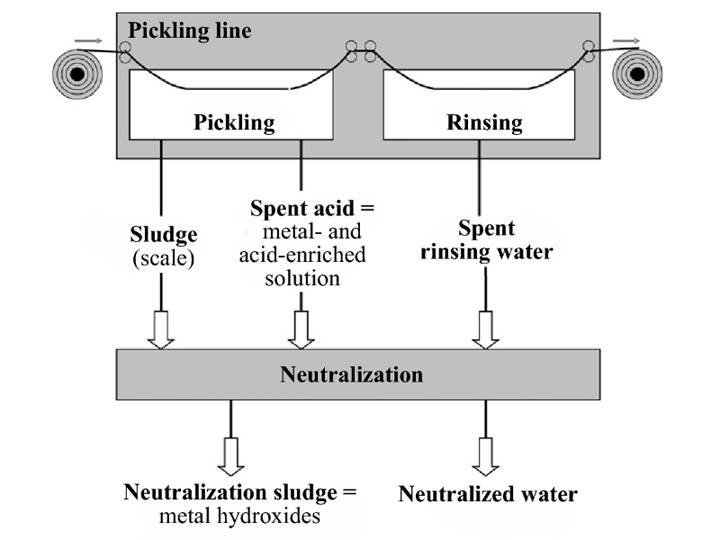

Inkqubo Flow

Ukuxhoma kumalungu esinyithi → ukucocwa kweekhemikhali (ikhemikhali yealkaline yokucoca eqhelekileyo okanye i-surfactant degreasing) → ukuhlamba ngamanzi ashushu → ukuhlamba ngamanzi abalekayo → inyathelo lokuqala lokuchola → Ukuhlamba amanzi abalekayo → Inyathelo lesibini lokuchola → ukuhlamba amanzi abalekayo → tshintshela kwinkqubo elandelayo (njengaleyo njenge: Ukufaka imibala ngeekhemikhali → ukurisayikilishwa → ukuhlamba amanzi abalekayo → ukuqinisa unyango → Ukuhlamba → Ukuvala Unyango → Ukuhlamba → Ukomisa → Kugqityiwe).

Iziphene eziqhelekileyo

Iron oxide scale intrusion: Iron oxide scale intrusion yingxaki engaphezulu eyenziwe ngexesha lokuqengqeleka okushushu. Emva kokuchola, isoloko icinezelwe ngendlela yamachaphaza amnyama kunye nemicu, umphezulu urhabaxa, unesandla esivakalayo, kwaye ubonakala ngokungaqhelekanga okanye ngamandla. Ihlala ibangelwa yinkqubo yokufudumeza engafezekanga, inkqubo yokuhla kunye nenkqubo yokuqengqeleka kwe-pickling.

Indawo yeoksijini (umzobo wobume bomhlaba): ibhekisa kwinkangeleko efana nechaphaza, emgceni okanye enjengomngxuma eshiywe emva kokuba isikali se-iron oxide esikumphezulu wentsimbi eqengqelekayo ihlanjiwe. Ukuqengqeleka kucinezelwe kwi-matrix, egxininiswe emva kokukhetha. Inempembelelo ethile kwimbonakalo, kodwa ayichaphazeli ukusebenza.

I-Macular: amabala aphuzi avela kwinxalenye okanye yonke indawo yebhodi, engakwazi ukugqunywa emva kwe-oiling, echaphazela umgangatho kunye nokubonakala kwemveliso. Esona sizathu siphambili kukuba umsebenzi womphezulu wetanki ephuma nje kwitanki yokuchola uphezulu, amanzi okuhlanjwa ayasilela ukuhlamba umcu ngokuqhelekileyo, umqadi wokutshiza kunye nomlomo wetanki yokuhlambulula uvalekile, kwaye iiengile azilingani.

Ukuvuthwa ngaphantsi: Umphezulu wentsimbi yomtya unezikali ze-iron oxide zasekuhlaleni ezingasuswanga ngokucoceka nokungonelanga, kwaye umphezulu wepleyiti unombala ongwevu-mnyama, unamaxolo entlanzi okanye amaza amanzi axwesileyo. Inento yokwenza nenkqubo ye-asidi, ngakumbi ngenxa yokuba i-asidi yoxinaniso ayinelanga, iqondo lokushisa alikho phezulu, i-strip ibaleka ngokukhawuleza, kwaye umcu awukwazi ukuntywiliselwa kwi-asidi.

Ukuvuthwa okugqithisileyo: Umphezulu wentsimbi yomtya uhlala umnyama mnyama okanye umdaka omnyama, ubonisa ibhloko, amabala amnyama agqabhukileyo okanye i-macular, kwaye umphezulu wepleyiti urhabaxa ngokubanzi. Isizathu sisichasi sokuchopha phantsi.

Ungcoliseko lweNdalo

Izinto ezingcolisayo eziphambili kwinkqubo yokuvelisa ngamanzi amdaka okucoca aveliswa yinkqubo yokuhlamba amanzi kuwo onke amanqanaba, uthuli oluveliswa yinkqubo ye-sandblasting, i-hydrogen chloride acid inkungu eveliswa yinkqubo yokukhetha, kunye nenkunkuma eveliswa yi-pickling, i-rising, phosphating, neutralization kunye neenkqubo zokuthintela umhlwa. Ulwelo lwetanki, intsalela yenkunkuma, into yokucoca inkunkuma, imigqomo ekrwada engenanto kunye nenkunkuma yokupakisha, njl. Ezona zinto zingcolisayo yihydrogen chloride, pH, SS, COD, BOD?, ammonia nitrogen, petroleum, njl.

Laser Ukucoca

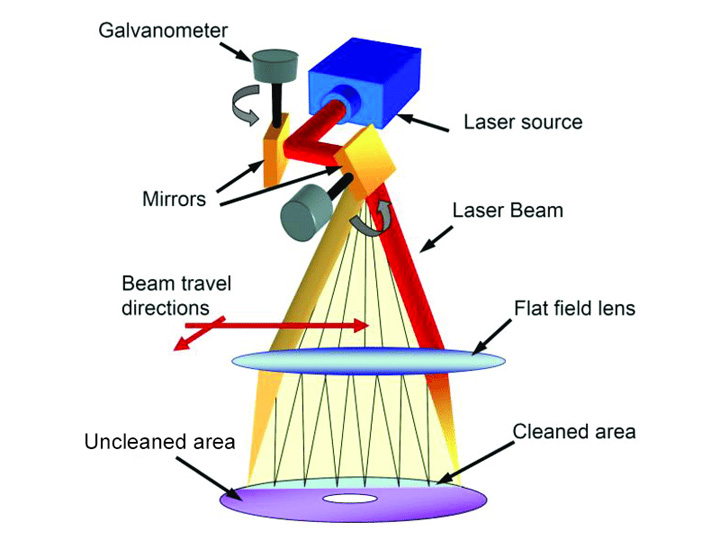

UMgaqo wokucoca

Umatshini wokucoca ngeLaserkukusebenzisa amandla e-laser ukungena kumphezulu wento. Ii-electron kwizinto eziphathekayo zifunxa ukungcangcazela kwamandla malunga ne-100 femtoseconds, kwaye zenze i-plasma kumphezulu wezinto eziphathekayo. Emva kwe-7-10 picoseconds, amandla e-electron adluliselwa kwi-lattice kwaye i-lattice iqala ukungcangcazela. Emva kwe-piccosecond, into iqala ukuvelisa ukushisa kwe-macro, kwaye izinto zendawo ezifakwe kwi-laser ziqala ukufudumala, ukunyibilika kunye nokunyuka, ukuze kufezekiswe injongo yokucoca.

Inkqubo yokucoca kunye nesiphumo

Xa kuthelekiswa nendlela yokukhetha, inkqubo yokucoca i-laser ilula kakhulu, akukho nto ifunekayo, kwaye umsebenzi wokucoca ukukhutshwa kweoli, ukukhutshwa kwe-oxide kunye nokususwa kwe-rust kunokwenziwa ngexesha elifanayo. Vula nje isixhobo ukuze ukhuphe isibane, emva koko usicoce.

Inkqubo yokucoca i-Laser inokufikelela kwinqanaba eliphezulu lokucoca kwimizi-mveliso yezinga le-Sa3, phantse akukho monakalo kubunzima, i-hydrophilicity kunye ne-hydrophobicity yezinto eziphathekayo. Icokisekile ngakumbi kunokuchola.

Okuhle nokubi

Ukuhamba kweNkqubo kunye neeMfuno zokuSebenza

Xa kuthelekiswa nesixhobo sokuchola esineenkqubo ezingaphezu kweshumi elinesibini, isicoci se-laser siphumelele eyona nkqubo ilula kwaye siphumelele inyathelo elinye. Inciphisa kakhulu ixesha lokucoca kunye nelahleko yezinto eziphathekayo.

Indlela yokukhetha ineemfuno eziqinileyo kwinkqubo yokusebenza: i-workpiece kufuneka ihlanjululwe ngokupheleleyo ukuqinisekisa umgangatho wokususwa komhlwa; ukuxinwa kwesisombululo se-pickling kulawulwa ukukhusela i-workpiece ekubeni i-corrode ngenxa yoxinaniso olugqithiseleyo lwe-asidi; iqondo lobushushu lilawulwa ngokwemigaqo yenkqubo ukuphepha umonakalo kwi-workpiece kunye nezixhobo ezibangela ukubola; i-tank pickling ngokuthe ngcembe ibeka i-sludge, evimba umbhobho wokufudumeza kunye nezinye izixhobo zokulawula, kwaye kufuneka zisuswe rhoqo; Ukongeza, kuyimfuneko ukunikela ingqalelo kwixesha lokukhetha, uxinzelelo lwenaliti, ukutshiza ukusebenza, izixhobo zokukhupha, njl.

Ukucocwa kweLaser kunokuqonda ukusebenza okufana nesidenge okanye kwanokusebenza okuzenzekelayo okungaqhutywanga mntu emva kokuseta iiparamitha kwinqanaba lokuqala.

Isiphumo sokuCoca kunye nokuNgcoliseka kwendalo

Ukongeza kwisiphumo esinamandla sokucoca, inkqubo yokucoca i-laser nayo inenzuzo yokunyamezelana okukhulu.

I-oxygen macular, ubomvu kunye nobumnyama buhlala buvela ngenxa yeempazamo ekusebenzeni kwendlela yokukhetha, kwaye izinga lokulahlwa liphezulu.

Uvavanyo lwelaser yokulahla amanzi lungqina ukuba nokuba ukucocwa kwelaser kugqithisile, kusenokukhanya kwentsimbi eyomeleleyo, kwaye akuvelisi ihydroxide kunye nolunye ungcoliseko, olungayi kuchaphazela iindlela zokusetyenzwa ezilandelayo ezifana nokuwelda.

Akuyi kubakho ungcoliseko lwendalo olufana nenkunkuma yolwelo kunye ne-slag kuyo yonke inkqubo yokucoca i-laser, eyona ndlela yokucoca eluhlaza.

Iindleko zeyunithi VS Iindleko zokuguqulwa

Isixhobo sokuchola sidinga iikhemikhali njengento esetyenziswayo, ngoko ke ixabiso leyunithi liquka ukuhla kwezixhobo + iindleko zokusetyenziswa.

Umatshini wokucoca weLaser awufuni izinto ezisetyenziswayo ngaphandle kokuthenga izixhobo. Ixabiso leyunithi kukuhla kwexabiso lezixhobo.

Ngoko ke, ubukhulu bomlinganiselo wokucoca kunye neminyaka emininzi, iphantsi kwexabiso leyunithi yokucoca i-laser.

Ukubunjwa komgca wokuvelisa i-pickling kufuna iinkqubo eziyinkimbinkimbi, kwaye umlinganiselo we-pickling agents wezinto ezahlukeneyo zetsimbi awufani, ngoko ke umgca wokuvelisa ukuguqulwa kufuna ixabiso elikhulu lokuguqulwa, kunye nezinto zetsimbi zicocwe ngexesha elifutshane. akatshatanga kwaye akanakuguqulwa ngokulula.

Akukho ndleko yokuguqulwa yokucoca i-laser: emva kokutshintsha iiparameters zesoftware yomatshini ofanayo wokucoca, umphumo wokucoca iplate yensimbi umzuzu omnye kunye ne-aluminium alloy ngomzuzu olandelayo unokufumaneka. Kukulungele ukuba amashishini aphumeze imveliso yeJIT eguquguqukayo.

Shwankathela

I-Pickling plate inoluhlu olubanzi kunye nesicelo esinzulu kwimveliso yokuvelisa, kwaye idlala indima efanelekileyo kwinkxaso yezoshishino. Nangona kunjalo, ngophuculo oluqhubekayo lweshishini lemveliso, ukuphuculwa kwezakhono kunye nohlengahlengiso lwesakhiwo nazo zenziwa ngokucothayo.

Ngokwandiswa kolwazi lwabantu ngokusingqongileyo, urhulumente kunye namashishini aneemfuno ezingqongqo zokuchola imigca yemveliso, kwaye imida yengeniso yamashishini anxulumeneyo iya incipha kwaye incipha. Imekobume iyonke ilungele ngakumbi ukucocwa kwelaser.

Mhlawumbi kule minyaka ilishumi izayo, ii-pickling sheets ziya kuba negama elitsha - ii-laser zokucoca iishiti.